English

Gaobao aluminum foil cutting machines are specialized equipment designed to precisely cut large aluminum foil rolls into sheets with specific dimensions. Widely used in packaging, food, and industrial sectors, these aluminum foil cutting machines ensure efficient customization of aluminum foil products, enhancing productivity and maintaining quality in production processes. If you want to know more about the price and cost of aluminium foil cutter, or aluminum foil roll cutting machine, Please do not hesitate to contact the Gaobao non woven sheet cutting machine manufacturer.

1. Precision Cutting: Aluminum foil cutting machines offer accurate and uniform cutting, ensuring consistent sheet dimensions and smooth edges for reliable product quality.

2. Customization: These aluminium foil cutting machines allow adjustable settings, catering to specific sheet sizes required for packaging, food service, and industrial applications.

3. Efficiency: Automated operation and high-speed capabilities improve production efficiency, reducing labor costs and meeting industry demands.

4. Reduced Material Waste: Precise sheeting minimizes material wastage, optimizing the use of aluminum foil and contributing to cost savings in material-intensive industries.

Culinary Uses: The Gaobao aluminum foil cutting machine is instrumental in the food industry. It cuts foil into exact sizes needed for wrapping food items, lining baking trays, or covering dishes, aiding in food preservation and cooking processes.

Pharmaceutical Applications: The aluminum foil cutting machine is also beneficial in the pharmaceutical sector. It cuts aluminum foil into precise dimensions required for packaging medications, ensuring product safety and integrity.

Industrial Manufacturing: The aluminum foil cutting machine is used in various industries that utilize aluminum foil’s heat and electrical conductivity. It cuts foil into specific sizes needed for different manufacturing processes.

Arts and Crafts: The Gaobao aluminum foil roll cutting machine is also useful in the world of arts and crafts. It can cut aluminum foil into diverse sizes and shapes, providing materials for creative projects.

Construction and Insulation: The aluminum foil cutter machine is used in the construction industry where aluminum foil serves as an insulator. It cuts the foil into the right sizes for insulation purposes in buildings.

Beauty and Wellness: In beauty salons and health spas, aluminum foil is used for several treatments. The Gaobao aluminum foil cutter machine cuts the foil into appropriate sizes for these specific uses.

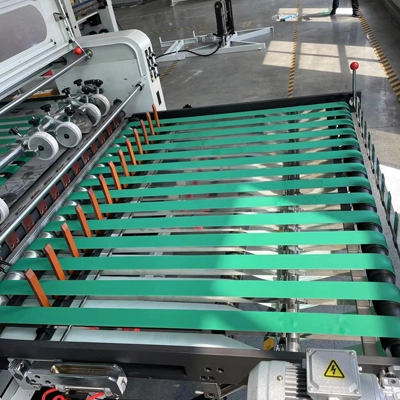

Feeding Mechanism: The aluminium foil cutting machine begins its process with a feeding mechanism, where a large roll of aluminium foil is loaded onto the machine. This roll is then unwound and guided through the aluminium foil cutting machine to the cutting area. The feeding mechanism is designed to ensure that the foil is fed smoothly and consistently, preventing any wrinkles or misalignments that could affect the quality of the cut.

Cutting Mechanism: At the heart of the aluminium foil cutting machine is the cutting mechanism, typically consisting of sharp, durable blades or a laser cutting system. For aluminium foil cutting machines using blades, they are often circular and can be adjusted to cut the aluminium foil to the desired length and width. Laser cutting systems, on the other hand, offer high precision by vaporizing the foil in the desired pattern without physical contact. The choice of cutting mechanism depends on the required precision, speed, and nature of the production.

Control System: Modern aluminium foil cutting machines are equipped with advanced control systems that allow operators to set the desired dimensions for the foil, including length and width, and control the speed of the cutting process. These control systems can be programmed for repetitive tasks, ensuring consistent quality and reducing the need for manual adjustments. They also monitor the operation for any potential issues, such as foil jams or maintenance needs.

Rewinding or Stacking: After the cutting process, the aluminium foil cutting machine either rewinds the cut pieces of foil onto a new roll or stacks them neatly for packaging. The rewinding mechanism is used when the foil is intended to be supplied in roll form, while the stacking mechanism is used for pre-cut sheets. This final step in the working principle of an aluminium foil cutting machine ensures that the finished product is ready for use or sale, with minimal manual handling required.

Maintaining an aluminium foil cutting machine is essential to ensure its optimal performance and longevity. Here are four key points for maintenance:

1. Regular Cleaning: Keep the aluminum foil cutting machine clean from dust, debris, and residue. Clean the cutting blades, rollers, and other components regularly to prevent buildup that could affect the cutting precision.

2. Lubrication: Follow the Gaobao manufacturer's guidelines for lubricating moving parts. Proper lubrication reduces friction, enhances operational smoothness, and prolongs the life of the aluminum foil cutting machine.

3. Tension Control: Regularly check and adjust the tension control systems to maintain consistent tension on the aluminum foil. This ensures proper handling of the foil during the sheeting process.

4. Inspection and Calibration: Periodically inspect the aluminum foil cutting machine's components for wear, damage, or misalignment. Calibrate the aluminium foil cutting machine as needed to ensure accurate cutting and consistent quality.

By implementing a comprehensive maintenance routine, you can prevent breakdowns, ensure precise cutting, and extend the service life of your aluminium foil cutting machine.

Aluminum foil cutting machines can process various types of aluminum foils, including household foil, industrial foil, and specialty foils used in different industries.

The aluminium foil cutter machine incorporates adjustable settings for length and width, allowing operators to customize sheet dimensions accurately according to specific product requirements.

Yes, aluminum foil cutting machines are designed to handle varying thicknesses of aluminum foil. Operators can adjust settings to accommodate the specific foil thickness being processed.

Utilizing an aluminium foil cutting machine offers benefits such as accurate sheet cutting, customized sheet sizes, increased production efficiency, reduced material waste, and enhanced product quality in industries reliant on aluminum foil materials.

Boost your company's productivity and enhance your converting capabilities with Hightop's cutting-edge Converting Machines.

Tel:

E-mail:

Address:

No.9-11, Hairun Road, Binhai New District, Pingyang County, Wenzhou, Zhejiang, China