English

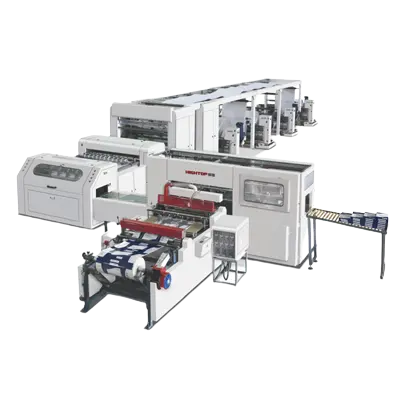

Gaobao's paper sheeting machines are specialized equipment designed to accurately cut large paper rolls into precise sheets. Paper sheeter machines find applications in the printing, packaging, and paper industries, ensuring efficient and uniform sheeting for various paper-based products. These paper sheeter machines enhance productivity and maintain consistent quality in paper processing. If you want to know more about paper sheet cutting machine prices, and various types of paper sheeter machine, paper sheet cutting machine, Please do not hesitate to contact the Gaobao sheet cutter machine manufacturer.

Paper sheeter machines convert paper rolls into sheets, a format more suitable for numerous applications.

The paper sheeter, also known as a paper sheet cutting machine, ensures precision and efficiency in the paper sheeting process.

Gaobao’s paper sheeting machine enhances productivity and reduces waste, contributing to more sustainable operations.

The paper sheeter machines are designed with advanced technology, ensuring accurate dimensions and smooth edges, vital for quality paper production.

Paper sheeter machines are a cornerstone of the paper industry, transforming paper rolls into usable sheets for various applications, including printing and packaging.

A paper sheeting machine, expertly developed by Hightop Paper Sheeter Machine Manufacturers, serves a pivotal role in the transformation of bulk paper rolls into precisely cut sheets, tailored to specific industry requirements.

Printing Industry: Paper sheets of various sizes are essential for printing projects, from letterheads and flyers to brochures and posters. Paper sheeting machines ensure consistent paper supply for printing presses.

Packaging Industry: Cardboard sheets, corrugated board, and other paperboard products form the backbone of the packaging industry. Paper sheeter machines provide precisely cut sheets for creating boxes, cartons, and other packaging materials.

Stationery and Paper Products: From printer paper and notebooks to envelopes and writing pads, paper sheeting machines create the foundation for a vast array of stationery and paper products we use daily.

Industrial Applications: Paper sheets are used in various industrial settings, such as for gaskets, insulation materials, and product laminates. Sheeter paper machines cater to these needs with precise cutting capabilities.

Aluminum foil slitting machines can process a variety of aluminum foils, including household foil, industrial foil, and specialty foils. The type of foil depends on the application and industry requirements.

Tension control ensures that the aluminum foil remains flat and even during the slitting process. Proper tension prevents wrinkles, tears, or irregularities in the slitted strips, resulting in consistent quality.

Yes, aluminum foil slitting machines are designed with adjustable settings to accommodate various roll widths. Operators can customize the width according to specific product needs.

Automation enhances efficiency and accuracy. Modern aluminum foil slitting machines incorporate automated controls, including alignment systems, tension control, and quality inspection, to ensure precise and consistent slitting.

Boost your company's productivity and enhance your converting capabilities with Hightop's cutting-edge Converting Machines.

Tel:

E-mail:

Address:

No.9-11, Hairun Road, Binhai New District, Pingyang County, Wenzhou, Zhejiang, China