English

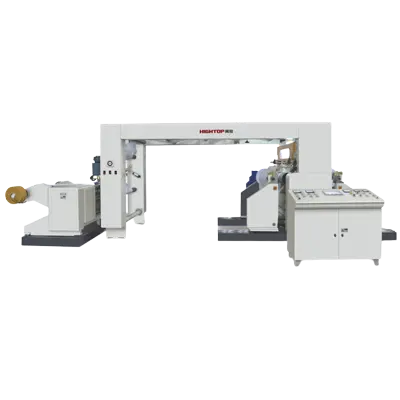

A plastic film slitting machine is an industrial equipment designed to precisely cut large rolls of plastic film into narrower and more manageable strips. Widely used in packaging, printing, and manufacturing industries, it enhances efficiency by creating uniform strips suitable for various applications while minimizing material waste. Gaobao slitting rewinding machine manufacturer provides various types of plastic film slitting machines, and Bopp tape slitting rewinding machines, Please do not hesitate to contact us!

1. Unwinding: The plastic film slitter unwinds the large roll of plastic film, creating a continuous sheet that passes through the entire process.

2. Web Guiding: An alignment system ensures the film remains straight and centered as it moves through the plastic film converting machine.

3. Slitting: The film passes through multiple rotary blades or knives that make precise cuts according to preset parameters, creating narrower rolls.

4. Tension Control: Tension control systems maintain consistent tension on the film during the slitting process to prevent stretching or deformation.

5. Rewinding: The slitted film is rewound onto separate cores, creating smaller rolls suitable for various applications.

6. Quality Inspection: Inspection mechanisms identify defects, irregularities, or deviations during the slitting process.

7. Automation and Precision: Advanced sensors, computer controls, and automation ensure accurate measurements and consistent results.

8. Waste Removal: Edge trimmings or excess material are typically collected and removed to minimize waste.

The process combines precision cutting, tension control, and automated systems to efficiently produce narrower plastic film rolls with consistent quality.

Plastic film slitting machines play a crucial role in various industries due to their significance in material processing and production. Here are four key reasons highlighting their importance:

1. Enhanced Efficiency: Plastic film slitting machines automate the process of cutting large rolls of plastic film into smaller, narrower rolls. This automation significantly increases production efficiency compared to manual cutting methods, saving time and labor costs.

2. Customization and Versatility: Industries require plastic films of varying widths for specific applications. Plastic film converting machines allow for precise customization, enabling manufacturers to produce plastic film rolls that meet the exact requirements of different products and markets.

3. Quality Control: These plastic film slitting machines ensure uniformity and precision in slitting, resulting in consistent product quality. Accurate cuts and tension control prevent defects and inconsistencies, meeting industry standards and reducing the likelihood of rejected or substandard products.

4. Reduced Material Waste: By optimizing the slitting process, plastic film slitting machines minimize waste generated during cutting. Plastic film slitters enable manufacturers to maximize the use of raw materials, reducing costs and contributing to sustainability efforts.

In essence, plastic film slitting machines streamline production, improve product quality, offer customization options, and promote resource efficiency in industries reliant on plastic film materials.

Packaging Industry: The plastic film slitting machine is extensively used in the packaging industry. It cuts large rolls of plastic film into smaller ones, which are then used to package a wide range of products, from food items to electronics, ensuring their safety and enhancing their shelf life.

Printing Industry: In the printing industry, the machine is used to create customized rolls of plastic film. These rolls are then used for various printing applications, such as labels, banners, and graphics. The ability to cut rolls to specific widths allows for greater flexibility and precision in printing tasks.

Textile Industry: The textile industry also benefits from the use of a plastic film slitting machine. The machine cuts plastic film into narrow rolls that are used in the production of synthetic fabrics or for wrapping and protecting textiles during transportation.

Medical Industry: In the medical field, the plastic film converting machine is used to produce rolls of plastic film used in the packaging of medical equipment and supplies. This ensures that these items remain sterile and safe for use.

Construction Industry: The construction industry uses plastic film for various purposes, such as moisture barriers or to protect surfaces during painting or remodeling. The plastic film slitting machine helps in cutting large rolls of plastic film into the required sizes for these applications.

Agriculture Industry: In agriculture, plastic film is used for purposes like greenhouse covering or mulching. The plastic film slitting machine helps in cutting the film into suitable sizes for these uses.

Plastic film slitting machines can process a wide range of plastic films, including polyethylene, polypropylene, PVC, PET, and more. The type of film depends on the application and the specific requirements of the industry.

Tension control in a plastic film slitting machine involves maintaining consistent tension on the plastic film throughout the slitting process. This ensures that the film remains flat and even, preventing stretching or wrinkles that could affect the quality of the final product.

Razor blade slitting involves using a rotating circular blade to cut through the plastic film, while shear cut slitting uses pairs of top and bottom blades to create a scissor-like cutting action. Shear cut is preferred for delicate films, while razor blade is more suitable for thicker materials.

Quality assurance involves regular maintenance of the machine, proper alignment of the film, accurate tension control, and thorough inspection of the final rolls for defects or inconsistencies. Implementing automated inspection systems can further enhance quality control.

Boost your company's productivity and enhance your converting capabilities with Hightop's cutting-edge Converting Machines.

Tel:

E-mail:

Address:

No.9-11, Hairun Road, Binhai New District, Pingyang County, Wenzhou, Zhejiang, China